What is a Closed Loop System in Material Handling?

In today’s fast-paced supply chain environment, businesses are constantly looking for ways to reduce costs, improve efficiency, and promote sustainability. One effective solution gaining popularity is the closed loop pallet system. This system focuses on reusing pallets, reducing waste, and optimizing logistics processes.

By incorporating a closed loop system, businesses can enhance their material handling operations while supporting eco-friendly practices. Learn what a closed loop pallet system is and how it can benefit your business in the long run.

What is a Closed Loop System?

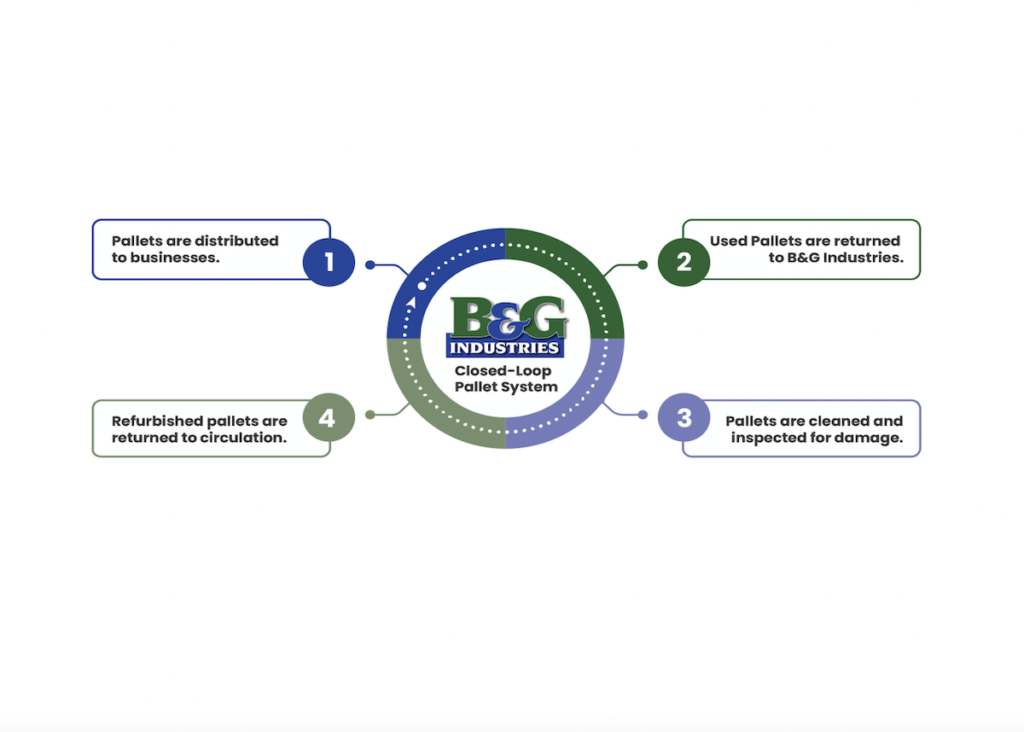

A closed loop system in material handling is an efficient way to manage the movement, storage, and transportation of goods using reusable materials, such as pallets. In this system, pallets are continuously reused rather than disposed of. After each use, pallets are returned, cleaned, inspected, and then put back into circulation for future shipments, creating a circular process that reduces waste and boosts efficiency.

What are the Benefits of a Closed Loop System?

1. Cost Savings

One of the key advantages of a closed loop pallet system is reduced costs. By reusing pallets, businesses minimize the need to purchase new ones, leading to significant savings on manufacturing, disposal, and replacement costs. The cost efficiency can improve the overall bottom line, especially for companies with high shipping volumes.

2. Environmental Sustainability

A closed loop pallet system is a sustainable solution that helps reduce waste and environmental impact. By reusing pallets instead of discarding them after each use, businesses lower their carbon footprint and reduce the demand for raw materials. This contributes to a more eco-friendly supply chain and aligns with green business practices.

3. Improved Efficiency and Reliability

In a closed loop system, pallets are regularly cleaned, inspected, and maintained to ensure they are always in good condition. This proactive approach minimizes the chances of pallet damage and product loss, leading to fewer disruptions in logistics. As a result, businesses can enjoy smoother operations, greater reliability, and fewer delays in their supply chain.

Why Choose a Closed Loop System?

A closed loop pallet system is a great solution for businesses looking to increase efficiency, reduce costs, and promote sustainability. By reusing pallets through a closed-loop process, companies can lower material waste, improve the reliability of their logistics operations, and streamline their supply chains.

At B&G Industries, we offer a variety of material handling solutions, including closed loop pallet solutions tailored to your business needs. With over 30 years of experience, we can help you implement a closed loop pallet system that improves your operations. Request a free quote today!